Gears

Gears are mechanical parts that help transfer movement. They’re literally everywhere in today’s society.

Resources:

- https://www.instructables.com/Basic-Gear-Mechanisms/

- https://uwaterloo.atlassian.net/wiki/spaces/EIC/pages/31720933400/Gears

- Mechanical Engineering for Makers page 169

- Gears Explained by Engineering Mindset

Other:

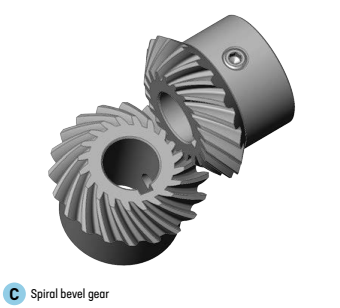

Types of Gears

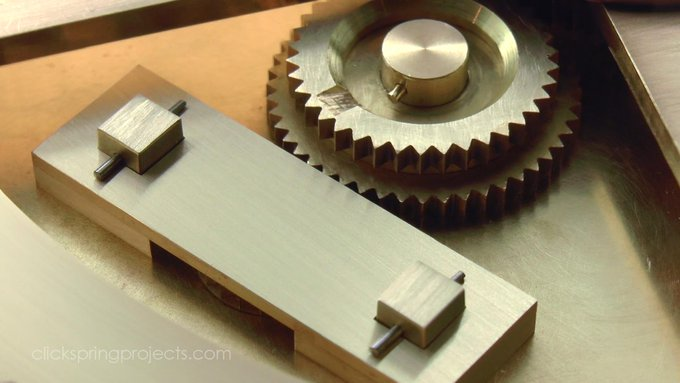

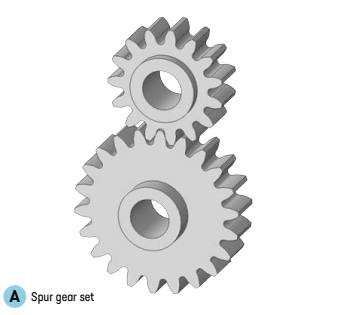

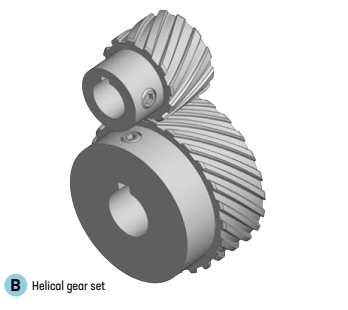

| Name | Image |

|---|---|

| Spur Gear |  |

| Helical Gear |  |

| Double Helical (Herringbone) Gear |  |

| Bevel Gear |  |

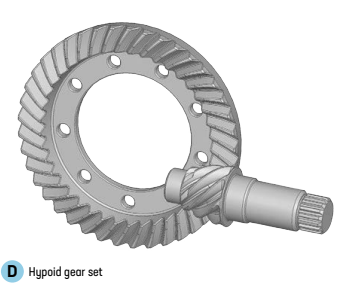

| Hypoid Gear |  |

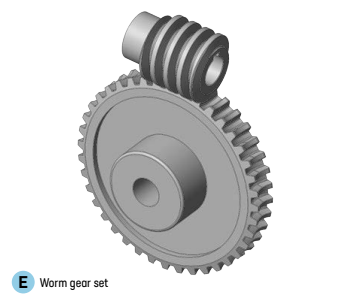

| Worm Gear |  |

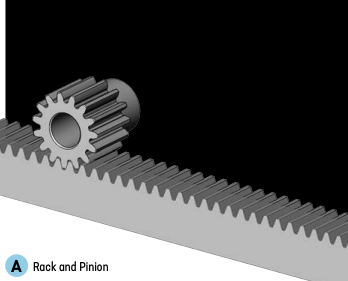

| Rack and Pinion Gear |  |

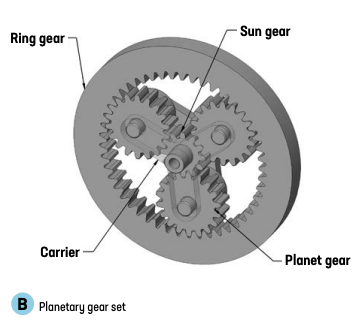

| Planetary Gear |  |

Spur Gears: Most common and simplest type. Work well at lower speeds, but noisy at high speeds because of the gear teeth impacting each other as they engage

Herringbone/Helical Gears: Are quieter, more smooth and have less backlash because the teeth make contact gradually along the profile. However, they lose some of the torque.

Bevel Gears: Used to transmit power between perpendicular, intersecting shafts.

Hypoid Gears: Excellent middle ground between a bevel gear reduction and a worm gear reduction.

Worm Gears: Offer some of the most dense and simple ways to achieve high reduction ratios.

Rack and Pinion Gears: Allows the translation of rotational motion to linear motion.

Planetary Gear: Transfer torque from colinear input shafts. Multiple stages can be added to increase the reduction achieved. See video

3D Printing

Different types of Gears

Spur gears: Gears that people are more familiar with, they’re regarded as the most efficient. They’re not idea for power transmission. Spur gears are used low speed applications, not high load load. small surface area of teeth make them more vulnerable to damage and wear in high stress situations.

Helical gears: Ideal and provide maximal power transfer, Helical gears help reduce wear because the force is exerted over a longer distance gradually mesh and distributes forces better, teeths gradually mesh and forces are transmistted gradually.

Dual-helical gears (Herringbone gear): Helps negate the axial forces, allows teeth to last longer. (ex: in RC Cars)

When 3D printing…

make sure to print in the right orientation so the forces are exerted perpendicularly.

Reinforcing small gears with screws.

Best material for strength: PolyMax Polycarbonate

Use rollar bearings and silicone lubricant.

Terminology

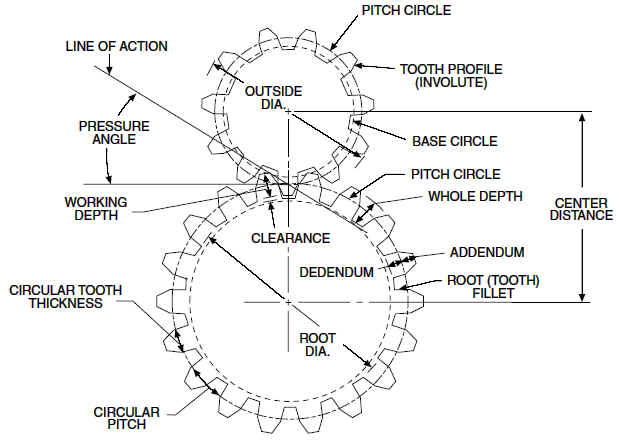

Parts of a gear

Axis, teeth, pitch diameter

Driver gear vs. Driven gear

The driven gear is the one that receives the forces.

Geartrain: This is just a series of gears.

Gearboxes: Takes the rotation of an input shaft, usually the axle of a motor, and through a series of gears alter the speed and power coming from the input shaft to turn an output shaft at a desired speed or torque. Gearboxes are usually classified in terms of their overall speed ratio, the ratio of the speed of the input shaft to the speed of the output shaft.

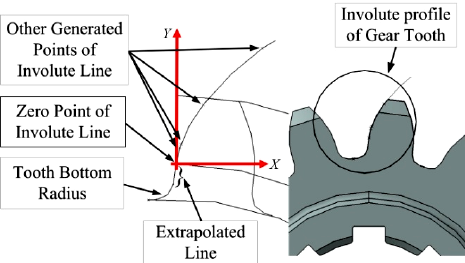

Gear Tooth Profiles

Involute Gear Teeth: By far the most common gears used today

Triangular gear teeth: simple to cut with hand tools like a file, have geometry that is easy to draw, and are adequate for light loads and slow speed